Composite Parts and Systems Manufacturing

Our Production Capacities

Composite Parts and Systems Manufacturing

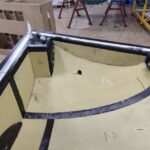

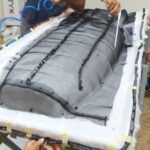

INMANO Aviation produces and assembles composite parts of aircraft and other systems using different production techniques at tolerances that meet customer requirements.

- INMANO can produce parts using Vacuum Bagging, Vacuum Infusion and Oven Post Curing methods.

- We can assemble complex composite parts with high-precision fixtures that we design and manufacture.

- We paint your composite parts with Acrylic, Epoxy and PU paints in matte, semi-gloss and gloss.

Mechanical performance of 3 mm thick material produced with 300gr/m2 unidirectional carbon/epoxy with vacuum bag.

Tensile Strength: 1100 MPa

Elastic Modulus: 124 Gpa

Compressive Strength: 340 Mpa

Compressive Modulus: 106 Mpa

Fiber Mass Ratio: 72%

Fiber Volume Ratio: 64%

Mechanical performance of 2 mm thick material produced with vacuum bagged 150gr/m2 +/- multiaxial carbon/epoxy.

Tensile Strength :554 MPa

Elastic Modulus :45 Gpa

Compressive Strength :335 Mpa

Compressive Modulus :42 Mpa

Fiber Mass Ratio :51%

Fiber Volume Ratio :42%

1000

m² Closed Production Facility

25

Years of Experience

400+

Parts Manufacturing

6

Activity in the Country